PRODUCT CATEGORIES

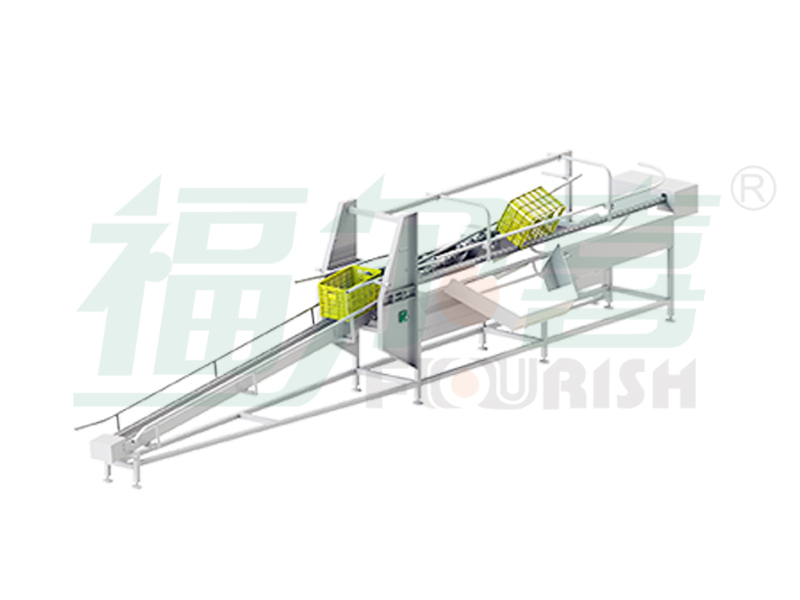

Chain type bin dumper

The chain type bin dumper is mainly suitable for collecting raw material by turnover basket. The workers only need to put the turnover basket in the feeding position of bin dumper. Transporting, turning over and dumping the basket can be automatically completed. Turnover baskets should be centralized in the inlet so as to reuse them conveniently. It can greatly reduce the labor force and improve the uniformity of feeding material.

Application:

Date, Citrus, Walnut, leechee

Characteristics:

Automatic feeding system can reduce work force and cost forcefully;

Feeding material is more uniform compared with the manual work, which can reduce load capacity of back-end equipment.

Simple and compact construction with stable running.

Technical parameters:

Model | Capacity (basket/h) | Total power(kw) | Max loading(t) | Dimension | ||

Length (mm) | Width (mm) | Height (mm) | ||||

MKS100 | 60 | 10 | 0.5 | 2050 | 2050 | 3600 |

LOCATION :

LOCATION :

Order Now

Order Now Collection

Collection